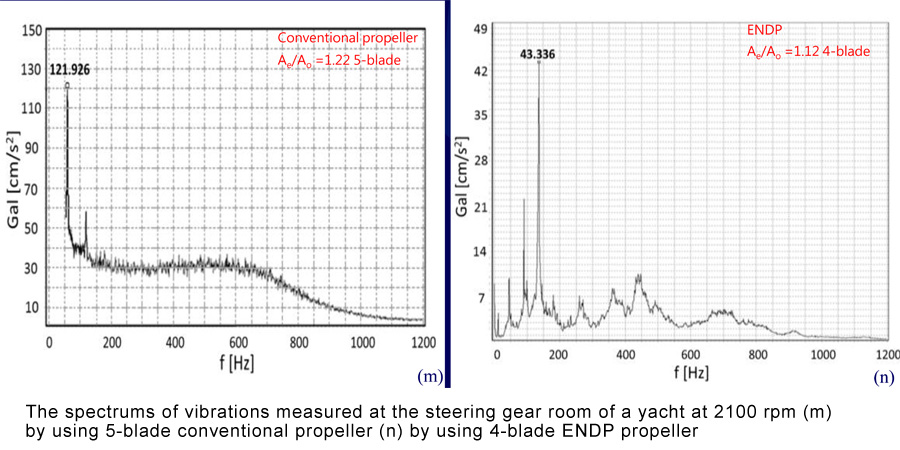

Sea trial

A 91-feet yacht equipped with a set of conventional or ENDP propellers is tested separately. The vibration spectrums are measured at the steering gear room. The position is top right side of the rudder. During the sea trial, the operating condition are the same for both sets of propeller.

In Fig m, when the yacht equipped with conventional propellers, the first blade rate amplitude induced by sheet cavitation is 121.9 Gals. and the broad band amplitudes caused by tip vortex cavitation at high frequencies are nearly 30 Gal. In Fig n, when the yacht equipped with ENDP propellers, the third blade rate amplitude induced by sheet cavitation is 43.3 Gals, and the broad band amplitudes at high frequencies caused by tip vortex cavitation are below 11 Gals.

From these sea trial results, it shows that the ENDP propeller can significantly restrain the tip vortex cavitation even with less blade number, and the reduction of back sheet cavitation is much better than the conventional propeller even with lower blade area ratio.